Plain Level Gauge Glass Green Color

- Product Item : HSLJ-0015

- Category: Level Gauge Glass

- Material:Borosilicate 3.3

- Standard:DIN7081

- Type:Transparent Level Gauge Glass Green Color

- Width:30/34mm, Thickness :17mm

PLAIN LEVEL GAUGE GLASS GREEN COLOR

also named

Transparent Flat Gauge Glass

Transparent Sight Glass,

Transparent Level Glass,

Transparent Level Gauge,

Flat Gauge Glass,

Plain Level Gauge Glass,

Plain Gauge Glass

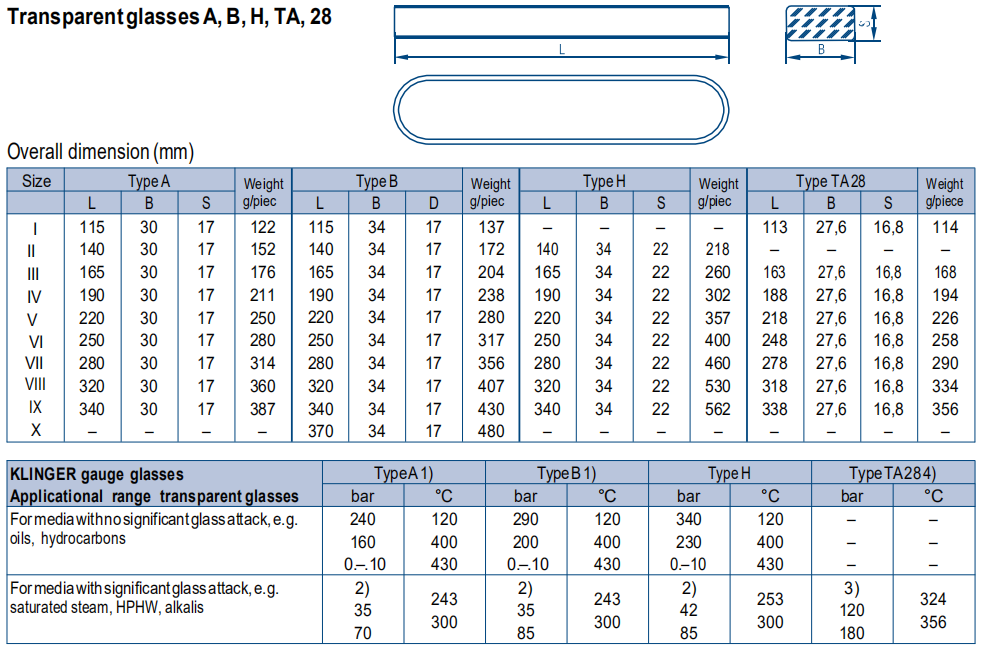

REGULAR SIZE AS FOLLOWS:

A1 115*30*17mm B1 115*34*17mm

A2 140*30*17mm B2 140*34*17mm

A3 165*30*17mm B3 165*34*17mm

A4 190*30*17mm B4 190*34*17mm

A5 220*30*17mm B5 220*34*17mm

A6 250*30*17mm B6 250*34*17mm

A7 280*30*17mm B7 280*34*17mm

A8 320*30*17mm B8 320*34*17mm

A9 340*30*17mm B9 340*34*17mm

A10 370*30*17mm B10 370*34*17mm

Transpaprent level gauge glass usually made of borosilicate glass and aluminosilicate glass.

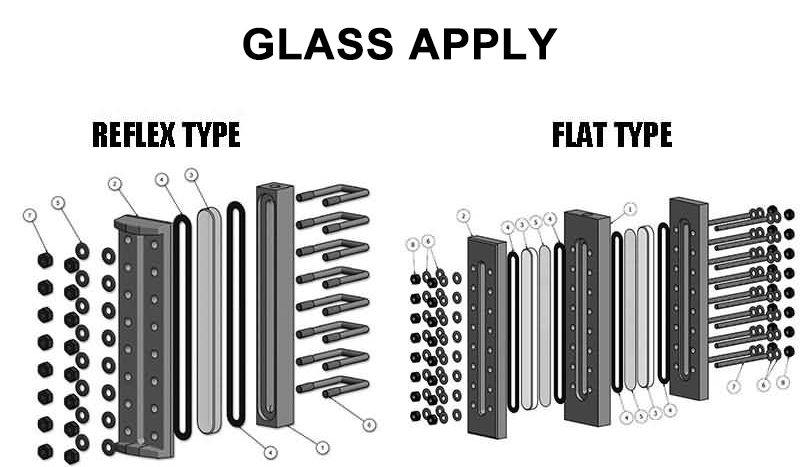

The glass is manufactured into the strip shape and used in boiler or some instruments for observing the liquid level.

Transparent type is also manufactured from "extra-hard" borosilicate glass. The surfaces on both sides are finely smooth and ensure optimal transparency.

A) One is as same with reflex Gauge Glasses,use molds to make the semi-finished products,afterwards,ground and polish the two side to ensure optimal transparency. By this manufacturing technique,the definition isn't good.

B)The other manufacturing technique is made of High Borosilicate sheet of 17mm thickness, cut the glass sheet according the detailed size and polish the side face for the smooth.This manufacturing technique glass is very clear,but the goods cost is higher.

It can be used with all media at service conditions up to 6MPa and temperatures up to 430 degrees centigrade.

APPLICATIONS:

In steam service above 35 bar and with media with a high pH-value.

Transparent glasses must be protected by a mica shield on the side facing the medium chamber. Transpar- ent glasses should always be chosen for contaminated, viscous or corrosive media. Within the given service limita- tions they may be used for all media ex- cept steam at pressures up to 340 bar or temperatures up to 400.°C.

PACKING:

KLINGER gauge glasses are packed in individual cardboard boxes. In addition to the glass, each package contains a KLINGER sealing gasket and cushion gasket and forms a complete unit ready for installation.

See trough - TRANSPARENT

For transparent level indicators, a two-sided observation system is used; direct observation through the crystals is allowed as the fluid rises or falls. These are mainly used in processes where the color of the liquid is of high importance for the process, or applications which require a protective mica.

MANUFACTURED IN ACCORDANCE TO DIN 7081

In order to achieve the standardization of this type of type of sigh glasses in all the different industries, the German regulatory institute, DIN for its acronym in German, designed standard parameters for the manufacture of this type of glass.

Among the main characteristics of this regulation are the dimensional parameters, the resistance to pressure, the chemical composition, the characteristics of the reflector prisms, the parameters of tolerances regarding parallelism, and the necessary acceptance tests.

STANDARIZED DIMENSIONS

The level sight glasses, both flat and reflex, have standard measurements dictated by a series of identification. The thickness of the sights is unchanged and remains at 17mm.

The width of the glasses can be either 30mm or 34mm, the latter being the most widely used. The length of the crystals varies based on the identification number, they go from number 1 to number 11. The most common are those mentioned in the table below.

OPERATING TEMPERATURE

The operating temperature should not exceed 280 ° C for continuous service.

The glasses that operate constantly between 280 ° C and 300 ° C must have protective micas, and the total operating service should not exceed 300 hours.

Temperatures over of 280 ° C can cause compressive stress on the glass, reducing it to 90% of its initial value for services from 300 hours to 300 ° C.

For resistance to thermal shock, check the operating pressure section. This is because at different pressures and temperatures, the stress on the glass increases and this affects its resistance to thermal shock.

CHEMICAL ATTACK RESISTANCE

In case the glasses are used in boilers, a decrease in mass is likely to occur; this due to the alkaline concentration in the water and its temperature.

The decrease in mass behaves according to the following table, in which the vertical axis represents the loss of mass in mm; the horizontal axis represents the time in ser-vice (in months).

The main attack in loss of mass occurs at temperatures above 200 ° C, for this reason, it is a safety requirement to replace the glasses, micas, and gaskets after any disassembly, or in accordance with the NORM DIN 7081. Under no circumstances should they be reused.

CATEGORIES

LATEST NEWS

CONTACT US

Name: Edward Lee

Mobile:0086-18830831810

Tel:0086-18830831810

Whatsapp:008618830831810

Email:info@lingjiekeji.com

Add:ROOM 718-722,RONGCHUANG BUILDING,TAOCHENG DISTRICT, HENGSHUI CITY, HEBEI PROVINCE ,CHINA,053000