Circular Sight Glass Disc - DIN7080

- Product Item : HSLJ-003

- Category: Circular Sight Glass

- Material:Borosilicate

- Standard:DIN 7080

- Type :Circular Type

- Diameter: 5-500 mm. Thickness: 1-30 mm.

CIRCULAR SIGHT GLASS DISC DIN 7080 FOR OBSERVING LIQUID FLOW AND LEVEL

It also named Round Sight Glass ,Round Gauge Glass ,Sight Glass Disc.

Manufactured in 3.3 Borosilicate Glass, these sight glasses are used in several applications where a good chemical resistance and low thermal expansion coefficient are required. A bad chemical resistance may cause glass to react and release unwanted substances in the process, such as arsenic which is formed with a non-borosilicate glass reacts with water.

Special dimensions of glasses are available upon request, where the minimum diameter is 10mm, and the maximum diameter is 350mm. The thickness can be manufactured to a minimum of 3mm and a maximum of 35mm. Do not hesitate to contact us for recommendations as to which sight glass fits your application the best.

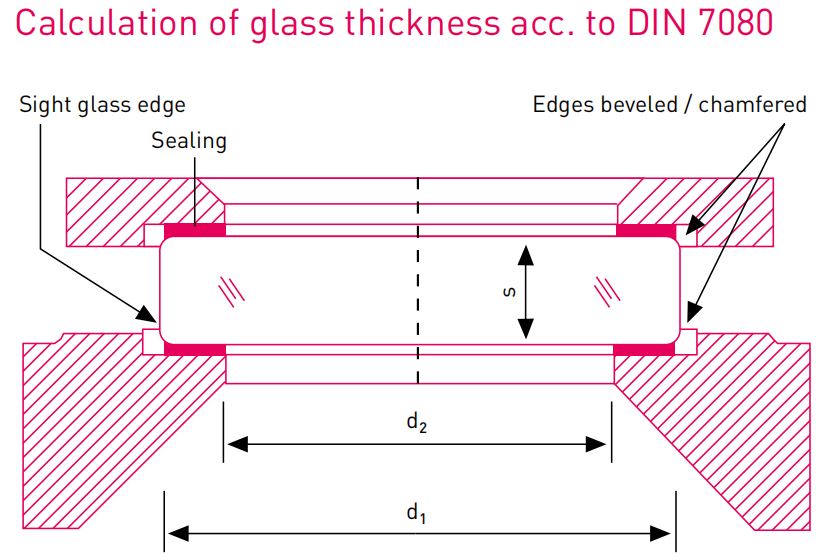

MANUFACTURED IN ACCORDANCE TO DIN 7080

In order to achieve the standardization of this type of type of sigh glasses in all the different industries, the German regulatory institute, DIN for its acronym in German, designed standard parameters for the manufacture of this type of glass.

The main issues this norm regulates is the pressure resistance in terms of the total diameter of the glass, the observable diameter of the glass, and the glass thickness. It also dictates permissible imper-fections in the glass, chemical attack, markings, and dimensional tolerances.

CHEMICAL ATTACK ON GLASS

The extent to which glass in boiler sight glasses is attacked when exposed to aqueous media will normally increase exponentially as the temperature and pH of the medium rises and the attack may be considerably accelerated by chemical additives such as those used in various ways and amounts in water treatment plants.

The resultant severe erosion and consequential dimensional changes may endanger the working safety of the sight glass and may result in rupture. The most important influencing variables are, however, the pH and temperature, but, for other complex reasons, the temperature plays a major role at temperatures markedly above 200 °C. To illustrate this, the figure below shows the erosion of a glass surface at 170 °C for two different pH levels, while the broken line shows the effect of increasing the temperature to 220 °C at a pH of 10 under laboratory conditions.

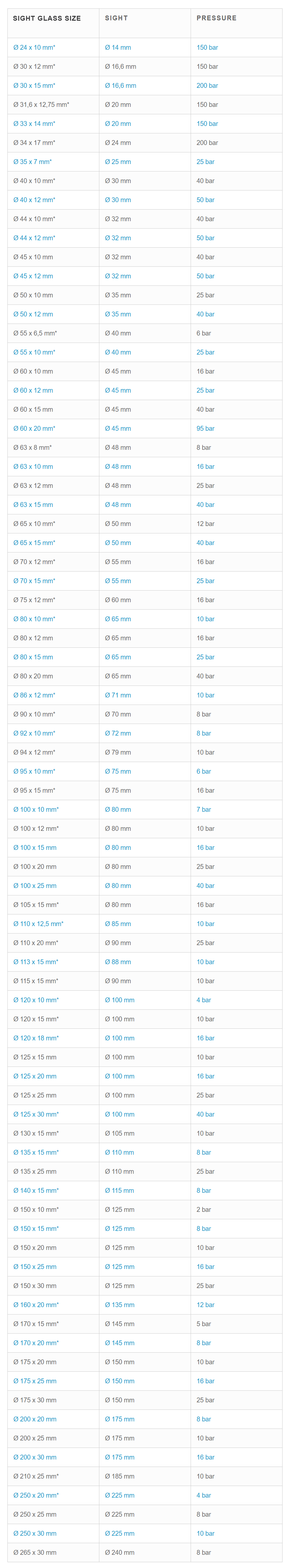

The DIN 7080 standard describes the glass quality and dimensions of the round sight glasses. The round sight glasses marked with * are not DIN 7080 sizes, but they are produced according to DIN 7080 and thus meet the same high quality standards.

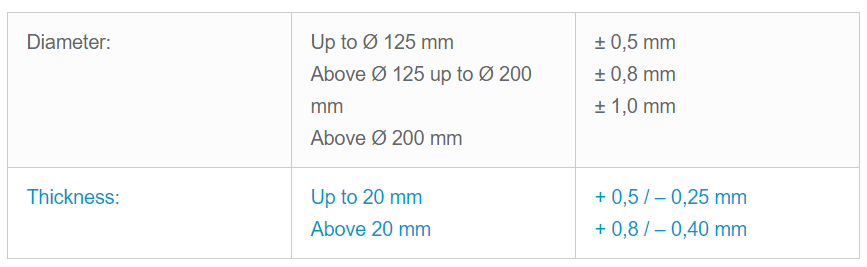

Diemensional tolerances DIN 7080:

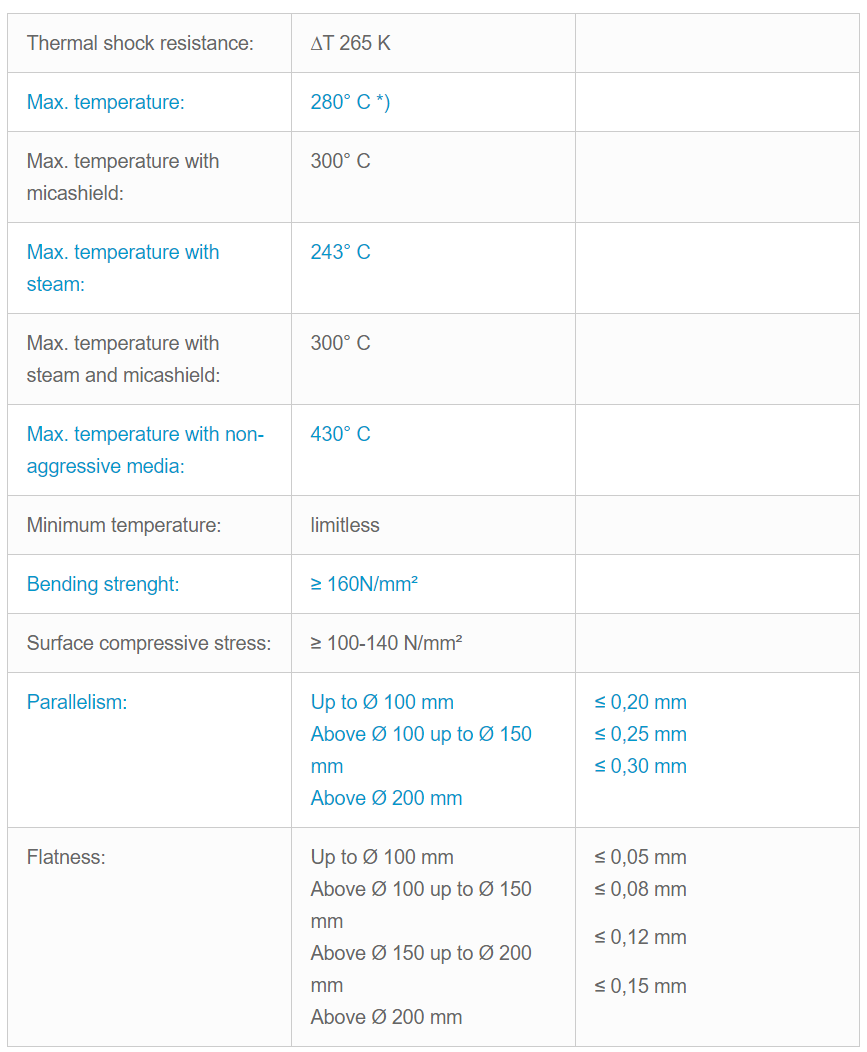

Technical characteristics:

⃰ ) When operating temperature exceeds 280° C, a permanent drop in the prestress is to be expected if no suitable measures are taken. The actual maximum permissible load on a sight glass always depends on the specific service conditions in question (pressure, temperature, nature of medium, type of armature).

CATEGORIES

LATEST NEWS

CONTACT US

Name: Edward Lee

Mobile:0086-18830831810

Tel:0086-18830831810

Whatsapp:008618830831810

Email:info@lingjiekeji.com

Add:ROOM 718-722,RONGCHUANG BUILDING,TAOCHENG DISTRICT, HENGSHUI CITY, HEBEI PROVINCE ,CHINA,053000